From a semi-destroyed spinning mill to a flagship in the textile industry

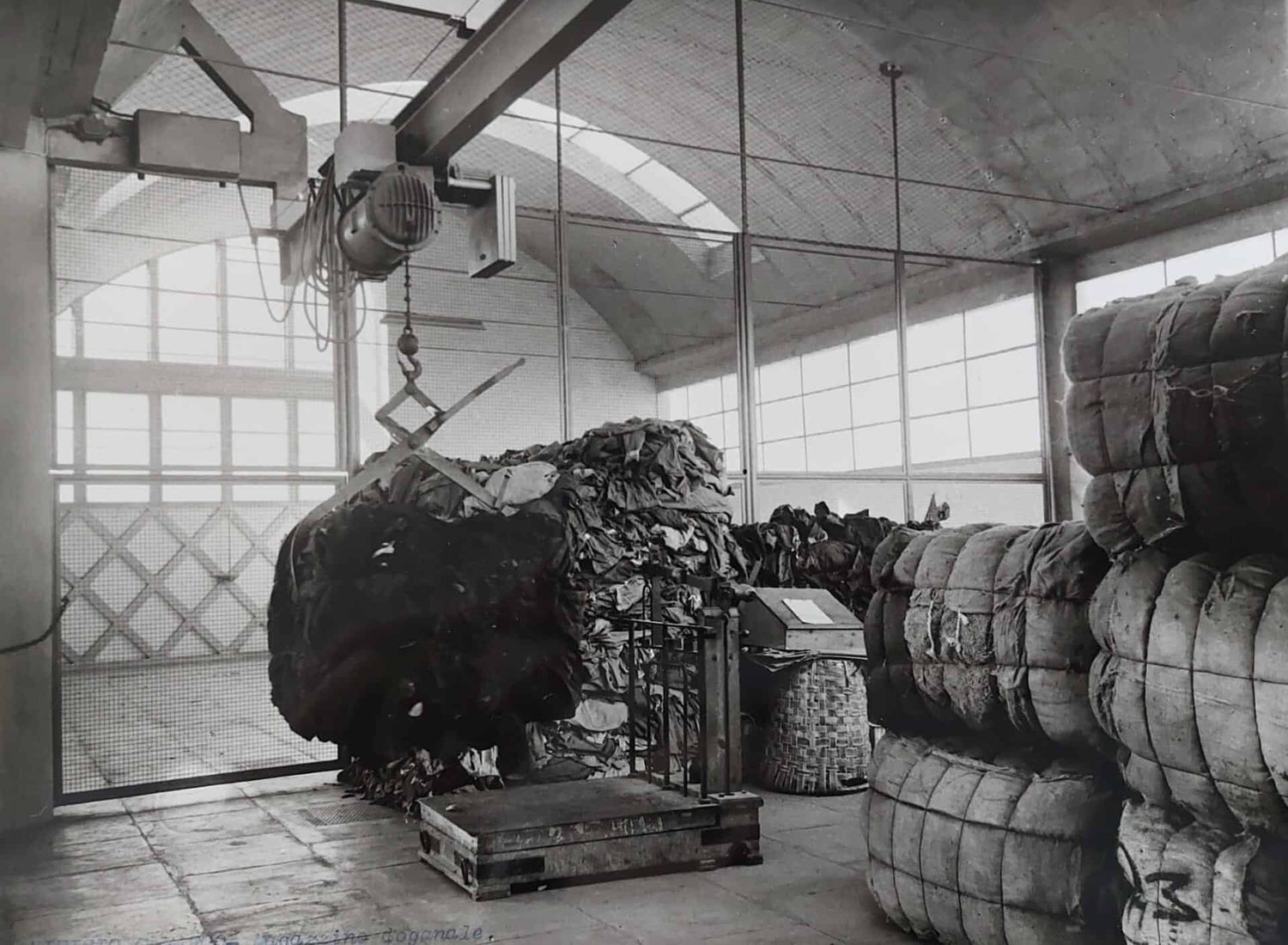

Our journey started back in the 1940s in a small town called Resina, close to Naples, where military goods were gathered from across Italy.

Croce Rossa and other charitable societies collected and sorted all manner of goods from blankets, knits, shirts and other military garments that were no longer wearable and sold them to the highest bidders.

At the time the situation in Italy was critical, with the country left devastated by the war. Meaning that there were just a small number of domestic sheep pastures, limited shipments of raw materials from abroad and no money to be invested, yet those military blankets and garments were made of high-quality and extra-fine worsted wool.

A story of great intuitions and determination that begins with Enzo Anacleto Mantellassi and continues for three generations

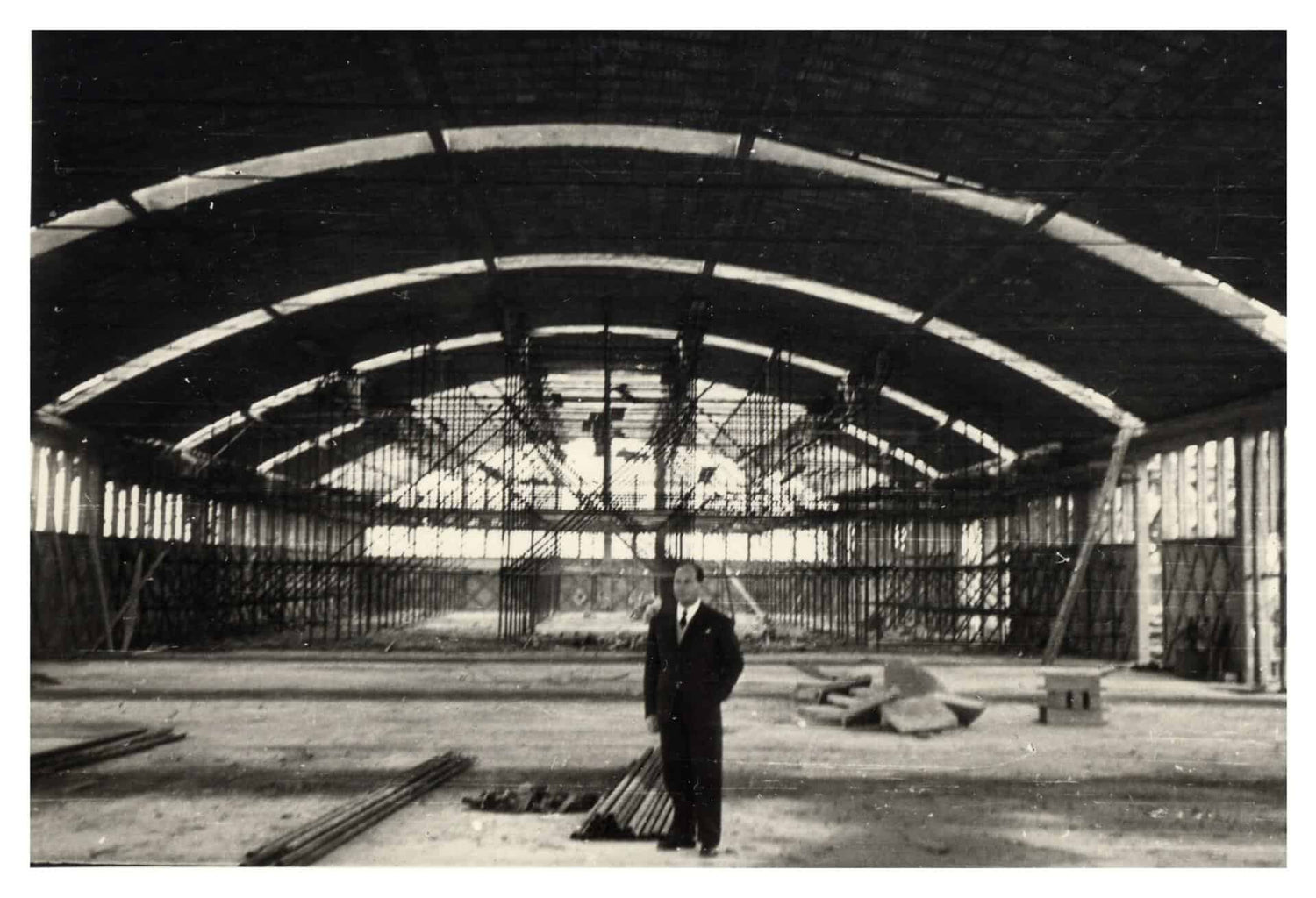

So our founder, Enzo Anacleto Mantellassi, who had just established our business by buying a semi-destroyed spinning mill, immediately understood the great potential in trading this commodity.

He established a process of having large quantities of second-hand military blankets and garments transported to Prato, where the goods began their transformation journey and were brought back to life.

Each garment was shredded, then spun to create precious recycled wool yarns, all without using chemicals, simply through a mechanical and wet process, and this process is still used today.

In the beginning, there were restrictions due to the material, that created thick yarn and also the colour: military green, khaki, brown and navy, therefore initially Enzo weaved these to create heavy blankets rather than fabrics.

With the passing of years, the gathering that was done in Resina was no longer enough for the business

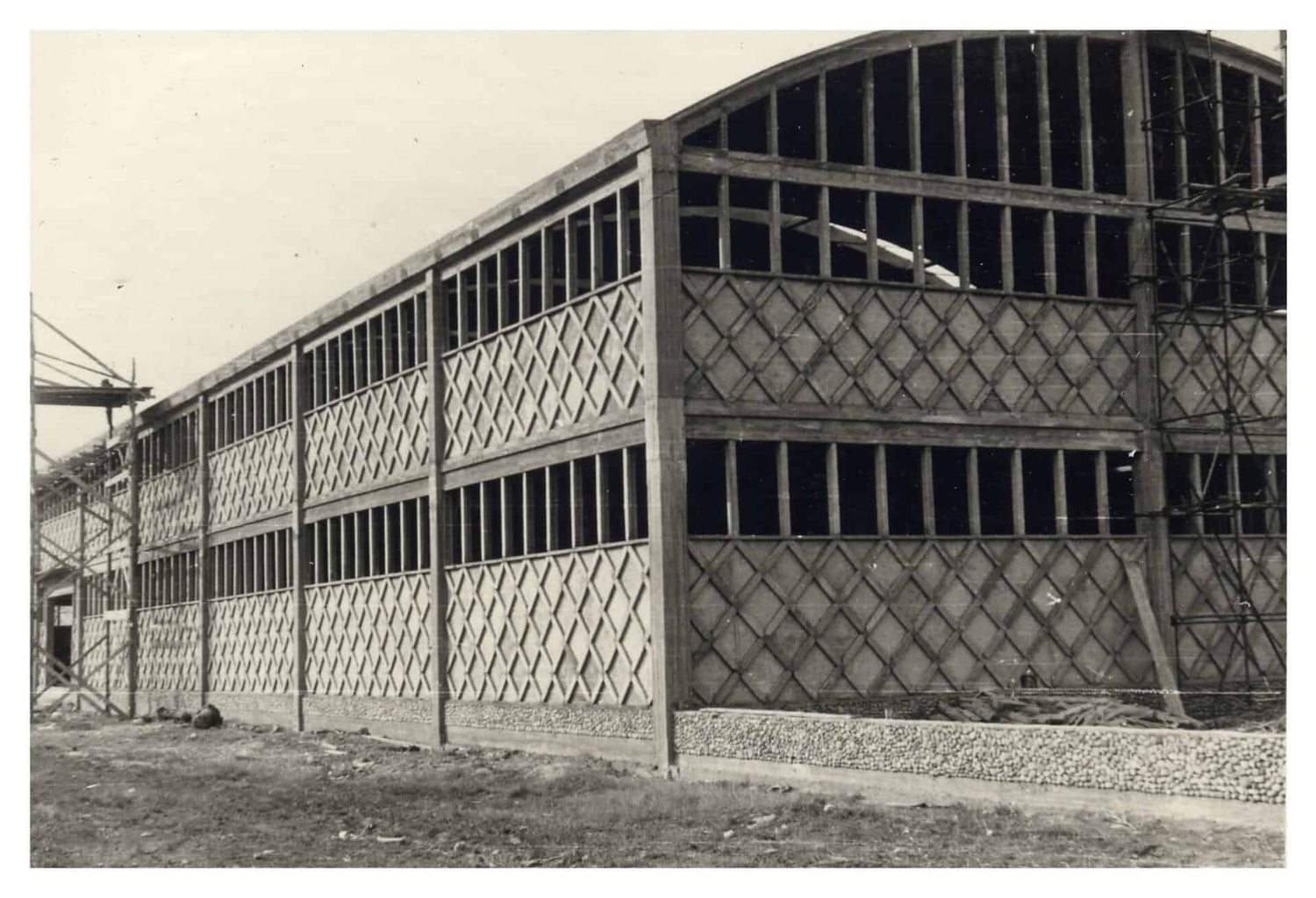

So Enzo decided to set up his own, by conceiving an innovative system divided into three floors.

The third floor was used as a gathering place, where unsorted garments and blankets were divided by hand according to composition and micronage, then passed to the second floor through specific holes.

The second floor was yet another sorting place, when the sorted garments were re-sorted by color and shade, in order to create homogeneous bales.

The first floor represented the place where these garments and blankets were given a new life: They were all shredded and prepared for carded spinning processes.

During the years, our family business has refined the recycling processand taken it to the luxury world

In fact, we are now able to produce an endless range of undyed regenerated wool colours through the Recype® process, and we also offer a wide range of luxurious fabrics with different constructions, weavings and finishings, all made with our next-generation of recycled wool, MWool®.

Nowadays, Manteco constantly pursues the objectives of growth and expansion, always with an eye to enhancing our values of sustainability, innovative solutions and improving our flagship zero-waste system, our sustainable design and traceable circular economy projects.

We are adhering to the principles of the UN Agenda 2030 for sustainable development and was the first textile company to ever apply a science-based LCA (Life Cycle Assessment) study on its luxury recycled wool textiles.

Behind our green approach and premium quality fabrics, there are generations of know-how, heritage and our fully traceable and transparent Manteco System, a network of local artisans and small companies that follow our precise Supply Chain Commitments and high production standards.